Initial Report(part2): TSMC (TWSE:2330), 70% 5-Year Potential Upside (VIP, Fabian VERA)

Business Model

Foundry Model: Unlike integrated device manufacturers (IDMs) like Intel, TSMC operates on a pure-play foundry model. This means it manufactures chips designed by other companies. This model allows it to serve a wide range of customers, including some of the biggest names in the tech industry. Its efficacy as foundry vis-à-vis its competitors has been discussed in the section ‘Competitor Analysis’.

Customers: TSMC’s clientele includes major technology companies such as Apple, Qualcomm, Nvidia, AMD, and many others. These companies rely on TSMC for their cutting-edge chip manufacturing capabilities. By serving its clients, the rhetorical question of ,,How effective is TSMC helping its clients?’ deserves an answer

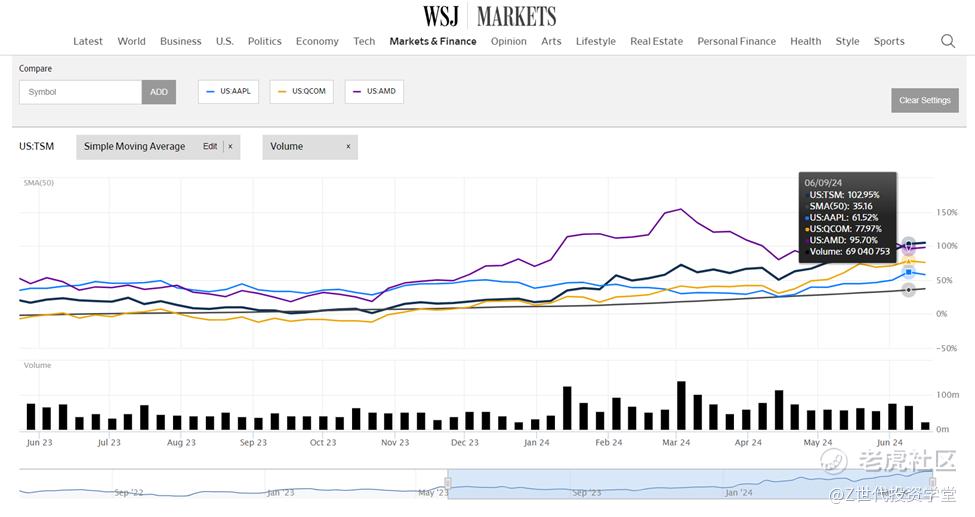

Fig. 6 – Multiple Valuation plot of TSMC and its clients, accompanied by stock performance

From Figure 6, TSMC is helping its clients in a manner that could be described as "a rising tide that lifts all boats” under the following lenses:

Overall Trend: All the companies shown (TSMC, Apple, Qualcomm, and AMD) have seen significant growth over the period displayed, with their stock prices trending upwards.

Correlation: The stock price movements of these companies are generally correlated, suggesting that they benefit from similar market conditions and technological advancements.

TSMC's Performance: TSMC (shown in black) has a strong performance, growing from around 50% to over 100% during the period. As the primary manufacturer for the other companies' chips, TSMC's success likely contributes to their performance.

Client Performance:

+ AMD (purple) shows the most dramatic growth, outperforming the others.

+ Apple (blue) and Qualcomm (yellow) also show steady growth, closely tracking TSMC's performance.

Interdependence: The similar growth patterns suggest a symbiotic relationship. TSMC's advanced manufacturing capabilities enable its clients to produce cutting-edge products, while the clients' demand drives TSMC's growth.

Semiconductor Ecosystem: The chart illustrates the interconnected nature of the semiconductor industry, where the success of the foundry (TSMC) and its clients (chip designers) are closely linked.

The lower part of Figure 6 offers an insight on valuation benchmarks of TSMC and its clients:

+The fact that these major tech companies are represented alongside TSMC indicates the crucial role the latter plays in its client’ supply chains. By manufacturing chips for its clients, TSMC enables them to focus on chip design while relying on TSMC's expertise and advanced manufacturing processes for production.

By manufacturing their chips, it maintains a position as a pure-play foundry and by consequent it doesn't compete with its customers by designing its own chips, allowing TSMC to serve a wide range of clients without conflict of interest. Curiously, Figure 6 shows Tesla (TSLA), which, while not typically considered a direct client of TSMC for chip manufacturing, is a major consumer of semiconductors for its electric vehicles and may indirectly benefit from TSMC's services through its suppliers.

For the sake of consistency, Figure 6 shows a basket of these stocks in two scenarios, with and without Nvidia, as this client has been captivating most of the financial commentary in recent weeks.

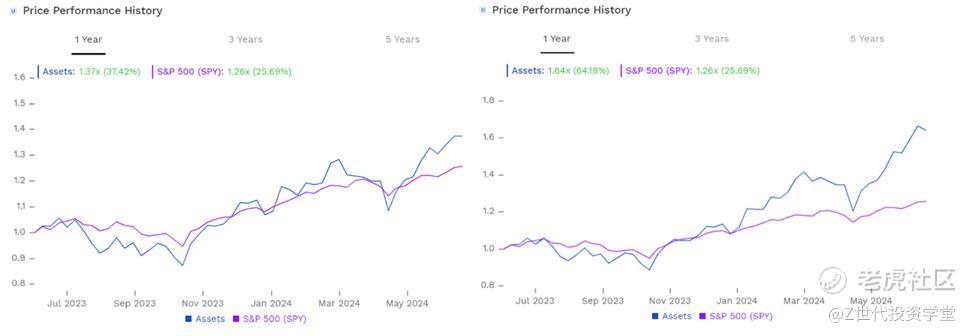

Fig. 7 – Stock Portfolio with Nvidia (right) and without (left) versus the S&P benchmark

Both portfolios generate alpha. Without Nvidia you get a decent alpha of 11.73%, enough to overcome any hurdle rate of 10% by a margin of 173 basis points on the left. With Nvidia you create an alpha of 38.49%, good for any ambitious hurdle rate above 20 percent.

Revenue Drivers

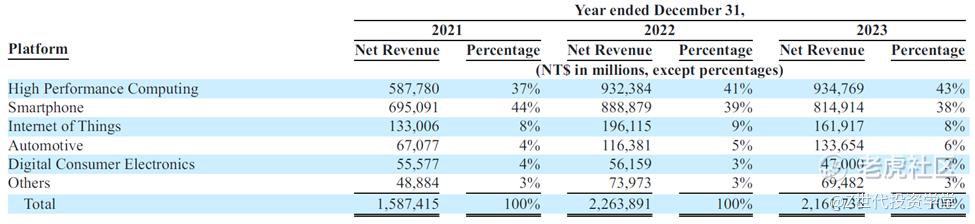

Table 2- Six industries of service signal diversification of revenue streams. 2023 TSMC SEC Filings.

On Table 2 we appreciate a decrease in net revenue from 2022 to 2023 mainly came from Smartphone of NT$73,965 million (8% year-over-year decrease), and from Internet of Things of NT$34,198 million (17% year-over-year decrease). The decrease was partially offset by an increase from Automotive of NT$17,273 million (15% year-over-year increase).

Such increase in net revenue from 2021 to 2022 came mainly from High Performance Computing of NT$344,604 million (59% year-over-year increase), and from Smartphone of NT$193,788 million (28% year-over-year increase). This increase also came from Internet of Things of NT$63,109 million (47% year-over-year increase)

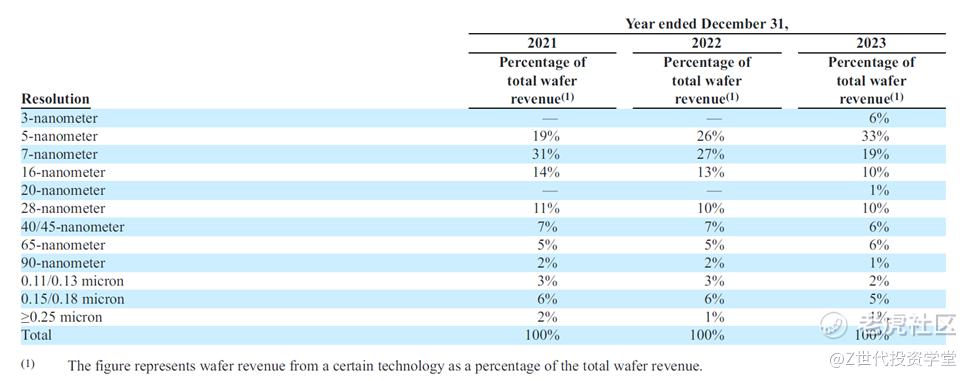

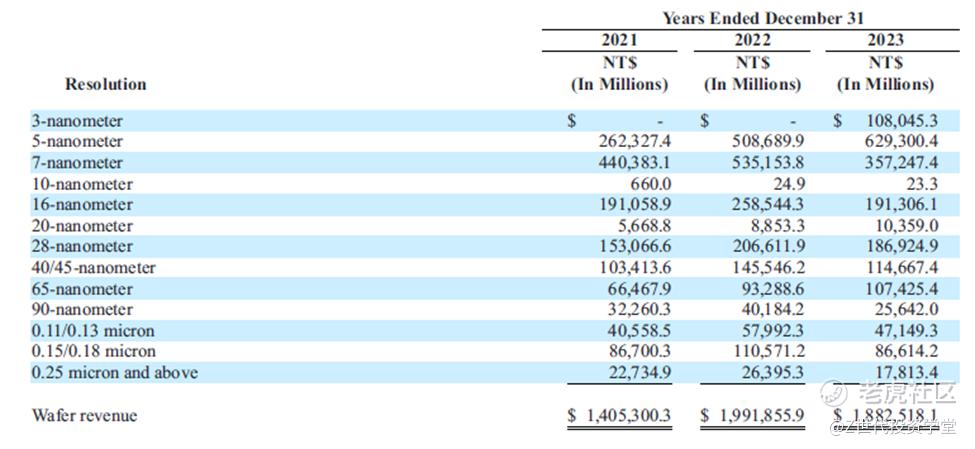

Table 3.- Revenue per nanometer resolution highlights rewards by innovation. 2023 TSMC SEC Filings.

In 2023, the 3-nanometer, 5-nanometer and 7-nanometer revenues represented 6%, 33% and 19% of total wafer revenue, respectively. Advanced technologies (7-nanometer and below) accounted for 58% of total wafer revenue, up from 53% in 2022. In 2022, the 5-nanometer and 7-nanometer revenues represented 26% and 27% of total wafer revenue, respectively. Advanced technologies (7-nanometer and below) accounted for 53% of total wafer revenue, up from 50% in 2021. Consolidated numbers are available on table 3, courtesy of 2023 TSMC SEC Filings, and unit economics are available on full display in [2].

Table 4.- Revenue per nanometer resolution in NT$ for 2021, 2022, and 2023. 2023 TSMC SEC Filings.

Cost drivers

Cost drivers is a combination of Transistor Density, Design, Energy, Assembly, Test, and Packaging Cost.

Transistor density.- Defined as the amount of chips a wafer can create at once from Fig. 2. A 300 mm diameter silicon wafer produces 71.4 chips of 610 mm2 GPUs on average, which is the chip OpenAI used in 2018 to train the breakthrough AI algorithm OpenAI Five for reference.

Design.- Annual growth rates in the cost of semiconductor fabrication facilities (eleven percent) and design costs per chip (24 percent) are faster than those of the semiconductor market (seven percent)[3]. And the approximate number of semiconductor R&D workers has been increasing seven percent per year. Costs of photolithography tools, the most expensive and complex segment of semiconductor manufacturing equipment (SME), have risen from $450,000 per unit in 1979 to $123 million in 2019 [4] And only one photolithography company, ASML in the Netherlands, now sells photolithography equipment capable of manufacturing the smallest 5 nm transistors.

Energy.- The chip we are discussing at Transistor Density has an estimated electricity cost of $0.07625 per kilowatt-hour to determine chip annual energy usage[5] We increase the energy costs by 11 percent to account for cooling and other costs based on Google’s report that its data centers have an average power usage effectiveness (PUE) of 1.11 [6]

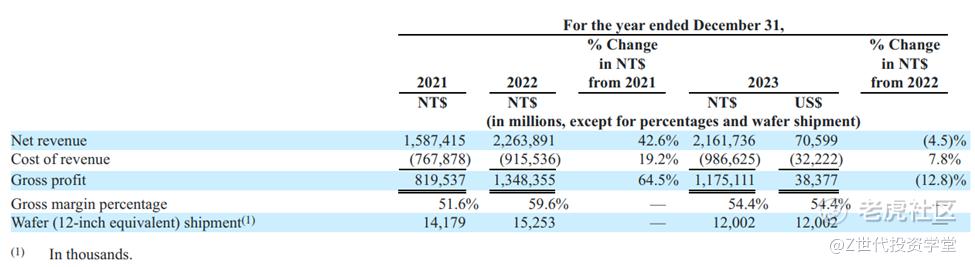

Assembly, Packaging Costs.- A decrease in wafer shipment can inflict a damage of 4.5% in revenue. Table 5 shows how shipping approximately 12 million 12-inch equivalent wafers in 2023 compared to 15.3 million in 2022 is partially offset by an increase in average selling prices (ASP) due to a higher proportion of advanced technology (7-nanometer and below) revenue and a depreciation of the NT dollar against the U.S. dollar.

Table 5.- Shipment impact on revenue. 2023 TSMC SEC Filings [10].

For reference purposes, outsourced semiconductor assembly and test (OSAT) firm costs can be obtained on the ratio of the foundry market to the assembly, test, and packaging (ATP) market [7]

*Do note that all of this is for information only and should not be taken as investment advice. If you should choose to invest in any of the stocks, you do so at your own risk.

Disclaimer: Investing carries risk. This is not financial advice. The above content should not be regarded as an offer, recommendation, or solicitation on acquiring or disposing of any financial products, any associated discussions, comments, or posts by author or other users should not be considered as such either. It is solely for general information purpose only, which does not consider your own investment objectives, financial situations or needs. TTM assumes no responsibility or warranty for the accuracy and completeness of the information, investors should do their own research and may seek professional advice before investing.